Introduction

As industries evolve and technology advances, the landscape of oil storage continues to transform. In this blog post, we’ll delve into the key considerations for utilizing silos in oil storage facilities in the year 2024. From technological advancements to regulatory changes, understanding these factors is essential for navigating the complexities of the modern oil storage industry.

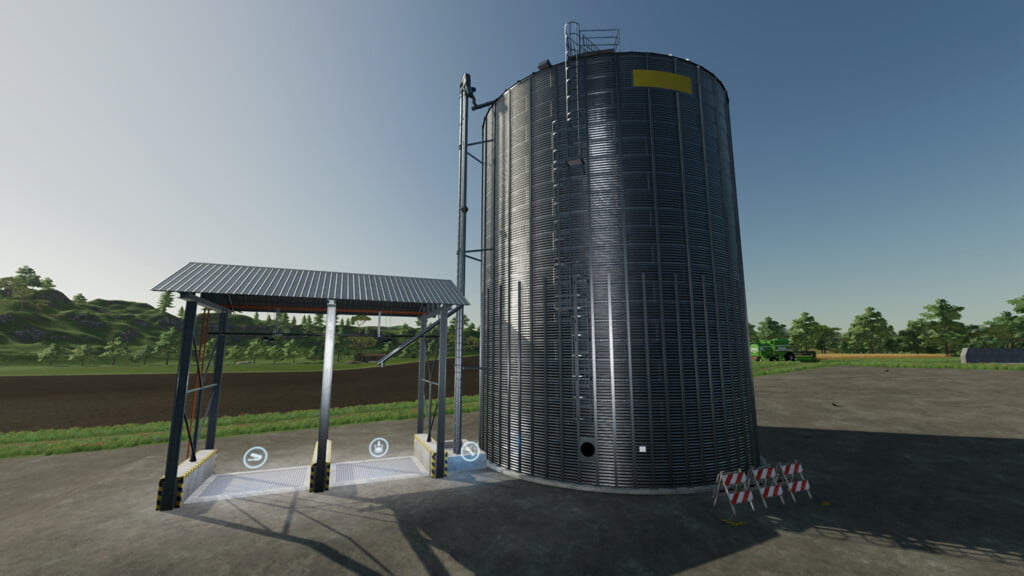

The Role of Silo for Oil Storage in 2024

In the dynamic landscape of the oil industry, the year 2024 marks a significant turning point with silo storage solutions emerging as indispensable assets. This pivotal role stems from a multitude of factors driving the surging popularity of silos for oil storage. Firstly, their unparalleled efficiency stands out as a defining feature. Silo storage optimizes space utilization by capitalizing on vertical storage, allowing for the accommodation of vast quantities of oil within a compact footprint. This efficiency not only maximizes storage capacity but also minimizes the need for additional storage facilities, thereby reducing operational costs and enhancing logistical efficiency.

Moreover, the versatility of silo storage solutions further cements their prominence in the oil industry. Silos can be customized to meet diverse storage requirements, accommodating various types of oil, including crude oil, refined products, and specialty oils. Whether it’s maintaining specific temperature conditions or facilitating seamless material handling processes, silos offer adaptability to suit the unique needs of different oil storage applications. This flexibility ensures that businesses can effectively manage their oil inventories while adapting to evolving market demands and regulatory standards.

Technological Innovations in Silo for Oil Storage

In the ever-evolving landscape of oil storage, the year 2024 heralds a profound wave of technological innovations revolutionizing the realm of silo for oil storage. This transformative shift is characterized by a plethora of cutting-edge advancements poised to redefine the future of oil storage facilities worldwide. At the forefront of these innovations are state-of-the-art monitoring systems, leveraging advanced sensors and analytics to provide real-time insights into crucial operational parameters. These systems offer unparalleled visibility into factors such as temperature, pressure, and inventory levels, empowering operators to proactively identify potential issues and optimize storage conditions with precision and efficiency.

Furthermore, automated loading and unloading processes represent another frontier of technological progress reshaping the landscape of oil storage. Incorporating robotics, automation, and artificial intelligence, these systems streamline material handling operations, minimizing human intervention while maximizing operational throughput. Automated loading systems ensure swift and accurate transfer of oil into silos, optimizing efficiency and reducing the risk of spills or accidents. Similarly, automated unloading processes facilitate seamless retrieval of oil from silos, enhancing supply chain agility and responsiveness to market demands.

Moreover, the integration of Internet of Things (IoT) technology and cloud-based platforms promises to revolutionize data management and decision-making in oil storage facilities. IoT-enabled sensors embedded within silos continuously monitor key parameters and transmit data to centralized platforms for analysis and interpretation. This real-time data analytics capability enables predictive maintenance, asset optimization, and informed decision-making, unlocking new levels of efficiency and productivity in oil storage operations.

Regulatory Compliance and Safety Standards

As the regulatory landscape surrounding oil storage evolves, the year 2024 underscores the critical importance of compliance and safety within the industry. With governments worldwide enacting increasingly stringent regulations to mitigate environmental risks and ensure public safety, oil storage facilities are facing heightened scrutiny and accountability. In this dynamic regulatory environment, it is imperative for oil storage operators to stay abreast of the latest requirements and implement robust safety measures to safeguard both personnel and the environment.

In 2024, oil storage facilities must adhere to a comprehensive set of regulatory requirements spanning various aspects of operations, including storage tank design, construction, maintenance, and spill prevention. Key regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Union’s REACH regulations impose stringent standards aimed at minimizing environmental impact and preventing hazardous incidents.

One of the primary regulatory requirements concerns the integrity and structural stability of storage tanks. Oil storage facilities are mandated to conduct regular inspections and assessments to ensure that tanks are structurally sound and free from defects that could compromise their containment capabilities. Additionally, strict guidelines govern the materials used in tank construction, specifying corrosion-resistant materials and protective coatings to mitigate the risk of leaks or spills.

Environmental Sustainability

In the wake of escalating environmental consciousness, sustainability has emerged as a paramount concern within the oil industry. With mounting pressure to mitigate environmental impact and embrace eco-friendly practices, oil storage facilities are increasingly turning to silo storage solutions as a sustainable alternative. In 2024, the adoption of silo for oil storage is driven not only by its operational efficiency but also by its inherent eco-friendly features that align with the industry’s sustainability goals.

One of the key eco-friendly features of silo storage is its ability to minimize waste generation. Unlike traditional storage methods that rely on disposable packaging and single-use containers, silos facilitate bulk storage, eliminating the need for excessive packaging materials. By consolidating oil storage into silos, facilities can significantly reduce the volume of packaging waste generated, thereby minimizing their environmental footprint and contributing to waste reduction initiatives.

Furthermore, silo storage solutions play a crucial role in reducing the carbon footprint of oil storage operations. Silos are designed to optimize storage space, allowing for efficient utilization of available land and resources. By maximizing storage capacity within a smaller footprint, silo storage minimizes the environmental impact associated with land use, land degradation, and habitat disruption. Additionally, the vertical storage configuration of silos helps reduce energy consumption associated with transportation and handling, further lowering carbon emissions and enhancing overall sustainability.

Cost-Effectiveness and Efficiency

In today’s competitive market, cost-effectiveness and efficiency are critical factors for businesses. Silo for oil storage offers significant cost savings through optimized storage space and streamlined operations. This section will explore the economic benefits of silos and how they contribute to operational efficiency in 2024.

| Economic Benefit | Description |

|---|---|

| Cost Savings | Silo for oil storage enables significant cost savings by optimizing storage space and minimizing the need for additional storage facilities. |

| Streamlined Operations | Silos streamline oil storage operations by facilitating efficient loading, unloading, and transportation processes, reducing labor costs and operational inefficiencies. |

| Bulk Purchasing | Silo storage allows businesses to purchase oil in bulk quantities, taking advantage of economies of scale and negotiating favorable pricing terms with suppliers. |

| Reduced Maintenance Costs | Silos require minimal maintenance compared to traditional storage methods, resulting in lower operational and maintenance expenses over the long term. |

| Improved Inventory Management | Silo storage solutions provide better control and visibility over oil inventory, reducing the risk of stockouts, overstocking, and inventory management errors. |

Conclusion

As we navigate the complexities of the oil storage industry in 2024, it’s clear that silo storage solutions play a pivotal role in meeting the evolving needs of businesses. By understanding the key considerations discussed in this blog post – from technological innovations to regulatory compliance and environmental sustainability – companies can effectively leverage silo for oil storage to achieve their goals in the years to come.

FAQ

Q: Are silos suitable for storing all types of oil?

A: Silos can be designed to store various types of oil, including crude oil, refined petroleum products, and specialty oils. However, it’s essential to consider factors such as temperature control, material compatibility, and regulatory requirements when selecting a silo for oil storage.

Q: How can I ensure the safety of oil stored in silos?

A: Safety measures for oil stored in silos include regular inspections, maintenance of equipment such as pressure relief valves and monitoring systems, and compliance with relevant safety standards and regulations. Implementing proper safety protocols and training for personnel is also crucial for ensuring the safe storage of oil in silos.

Q: What are the advantages of using silo storage for oil compared to traditional storage methods?

A: Silo storage for oil offers several advantages over traditional methods, including higher storage capacity, reduced environmental impact, cost-effectiveness, and easier compliance with regulatory standards. Additionally, silos provide better protection against contamination and ensure efficient utilization of space, making them an ideal choice for oil storage in modern industrial settings.